Powder less or no powder ™ Printers

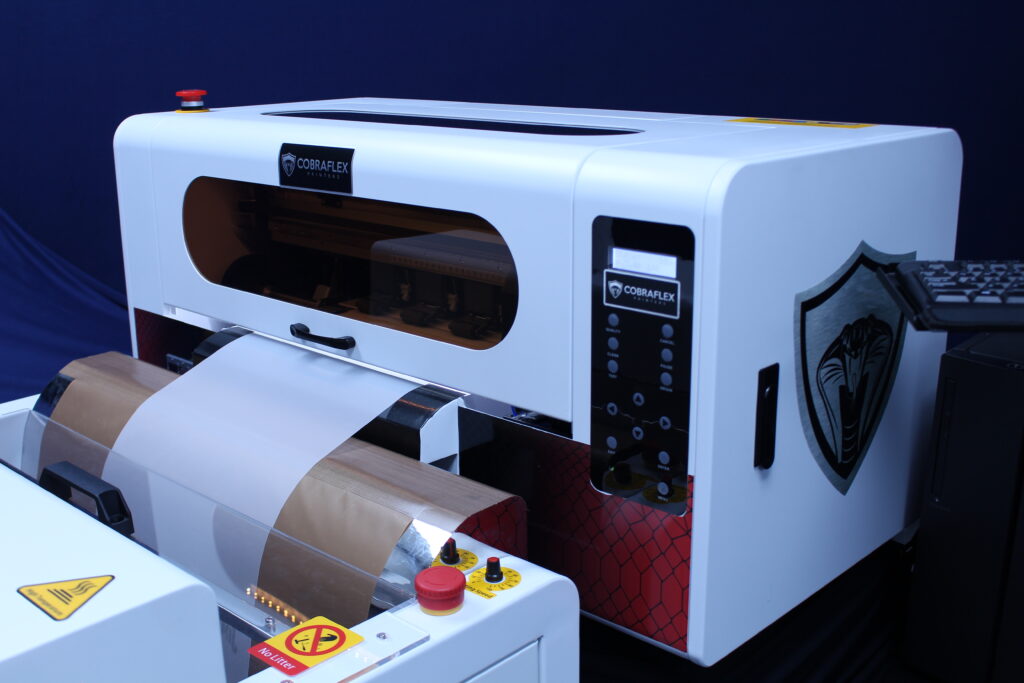

CobraFlex™: Revolutionizing the Printing Industry with Powderless Technology

Introduction Powderless Technology

Traditional powder-based printing methods have long dominated the industry, but CobraFlex has introduced a game-changing powderless technology. This innovation enhances efficiency, quality, and sustainability, marking a major shift in printing.

The Birth of CobraFlex

Developed in the U.S. in 2001, CobraFlex emerged as a response to the limitations of traditional methods. Key innovators pioneered this no-powder™ technology, reshaping the printing landscape.

How CobraFlex Works

Unlike powder-based printing, CobraFlex eliminates excess material, streamlining the process. This results in higher efficiency, improved quality, and reduced environmental impact.

Advantages and Applications

CobraFlex printers offer cost savings, cleaner production, and superior print quality. Their versatility spans industries, from apparel decoration to promotional product manufacturing.

Impact on the Industry

This technology has transformed printing workflows and business models, offering commercial printers a more sustainable and profitable alternative.

Challenges and Future Prospects

Early adoption faced hurdles, but ongoing R&D continues to refine the technology. The future promises further enhancements in efficiency and broader applications.

Conclusion

CobraFlex has revolutionized the printing industry by replacing powder-based methods with a cleaner, more efficient alternative. As advancements continue, powderless printing is set to define the future of the industry.